LED Bulb tube lamps assembly line led lamp making line machine

High speed led pick and place machine

MOQ :1 piece

Lead Time :30 Days

Seller Support : Trade Authenticity Guaranteed & Accepting

Payment : L/C,T/T,Western Union, Money Gram, Credit Card, Paypal

Product details

Supply Ability

- Supply Ability:100 piecesWarranty(Year):1 Year

Product Specifications

- Brand name:LEADSMT

Product Description

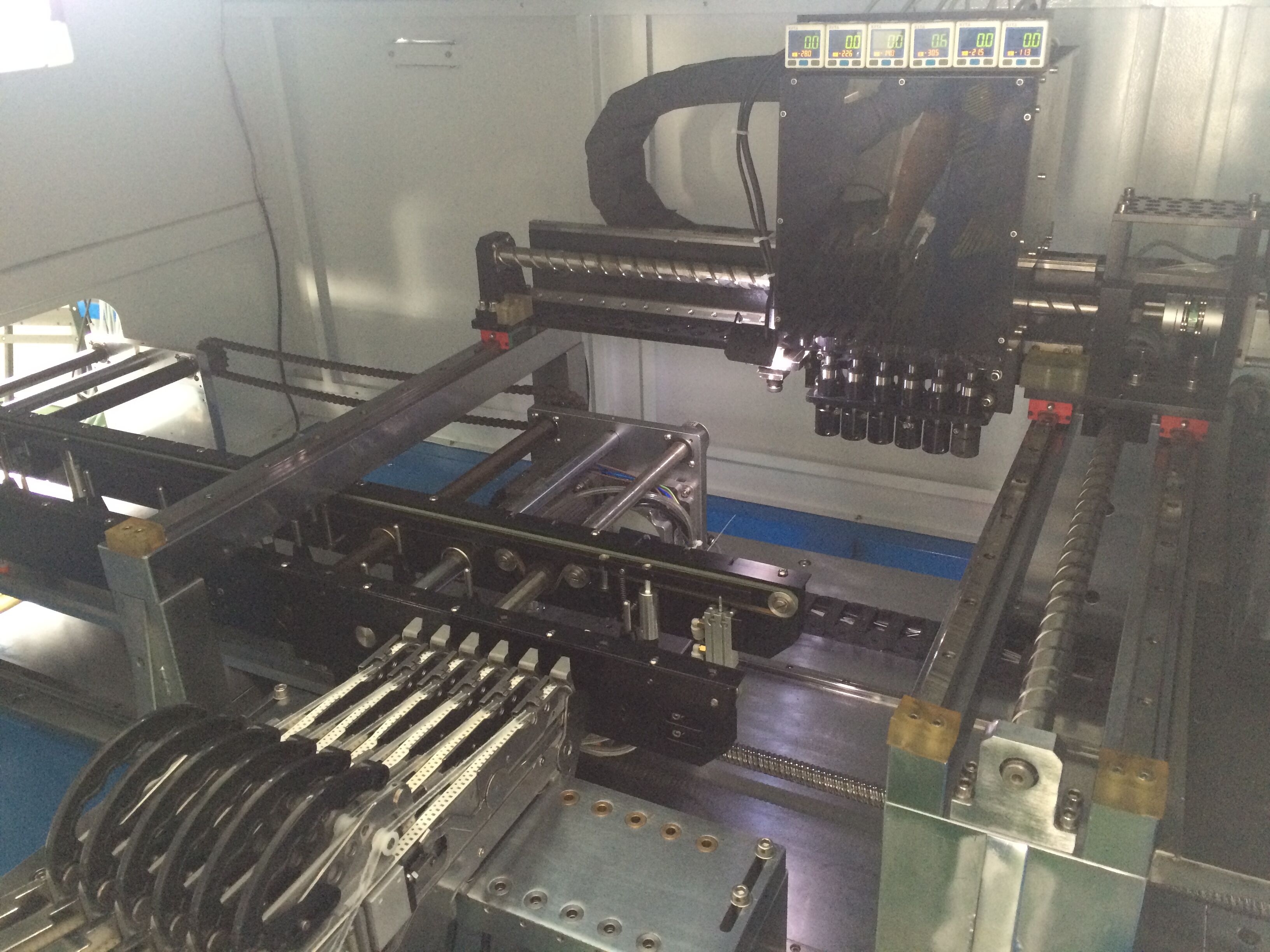

4 heads and 6 heads screw ball pick and place machine with high speed, high accuracy and long life time!

Specifications:

| Item | LED-1204TS |

| Mounting Heads | 4 pieces |

| Stable practical Speed | 18000cph |

| Max Speed | 22000cph |

| The accuracy of screw rod positioning | ±0.005 |

| Max Mounting pcb size | 1200mm*300mm(others made by your requirements) |

| Max moving range | X:1220mm, Y:430mm |

| Z axis max moving range | 15mm |

| pick and place components size | All above 0603 leds like 0603, 1206, 2014, 3014, 2835, 3528, 5050, 5630, 5730, 7070etc and resistors, IC, capacitors with the same size |

| Nozzles rotate angles | 360o can pick and place any sizes of components |

| Max No. of Feeders | 10 pieces |

| Feeder types | Pneumatic drive |

| Feeder sizes available | 8mm,12mm,16mm, 24mm ,32mm |

| Operation System | Windows XP or Windows 7 |

| Programming Method | PC +Visual Camera position |

| Dimensions | L2000*W900*H1500(MM) |

| Net Weight | Approx 700kg |

| Air Pressure | 0.6MPa (6kgf/cm2) |

| Power Supply | Single Phrase ,220V, 50/60Hz, 1.0 KW |

1. The Transmissionof platform adopts Panasonic Servo Motor, and imported rails to ensure itsstable and accuracy.

2. X.Y axis alsoadopts Panasonic Servo Drive, cooperated with imported liner guide rail ensuresits accuracy and speed.

3. X.Y axis adoptsNSK grind screw rod imported from Japan to ensure high precision and longlifetime, ultra-quietness under high speed.

4. Four pieces ofhigh-speed heads work at the same time, greatly improve the equipmentperformance. Nozzle adopts imported guide rail with high precision and durablelifetime. The rotation of nozzles use imported spline parts to ensure theaccuracy under rotation patch.

5. Easy operationalprogram, much more convenient, automatic vision makes position fixing moreaccurate and convenient.

6. Multi Feederoptional can meet different kinds of LED mounting.

7. DFI industrycomputer + Self special controller to provide the stability for Industrysystem, easy operate and learn.

8. Powerful softwareadopts numbers and images to display the program coordinate, easy and moreconvenient.

9. Software usedatabase system, it can save for different PCB programming: once programmingfor new product can use for life time!

10. Platform: Y axis,X axis can be moved manually, speed is adjustable, can achieve arbitrary pointmanual arrived, convenient programming.

11. Imported negativepressure detection system can check the suction accurately to prevent materialleakage and throwing.

12. Provide built-innegative pressure pump vacuum system: oil free and ultra quiet, long lifetime,vacuum pressure is constant.

13. Standard setting:1 set Industry control compute, 4 mounting heads,12 nozzles.

14. Optional:8mm,12mm,16,,and 24mm Yamaha feeder, different nozzles, air compressor .

You May Like

- Exhibitor

- Gold Supplier

- Trade Assurance

Business Type : Manufacturer

Company Location: GUANG DONG

Year Established: 17YRS

You May Like

-

LED Bulb tube lamps assembly line led lamp making line machine

-

Full Automatic led smt pick and place machine

-

Economic led pick and place machine

-

In-line high speed pick and place machine led automatic pick and place machine

-

LED lamp assembly line machines

-

Wave soldering machine

-

Economic led pick and place machine

-

Reflow oven LED soldering machine

-

Solder paste printer

-

High speed led pick and place machine